Our offer

Programming, visualisation, safety, consultancy and service

PLC programming

We programme mainly Siemens PLS controllers but, if required, we can also provide services related to programming of other controllers, e.g. Mitsubishi, Schneider, Beckhoff or Allen Bradley.

Visualisation of industrial processes

We will visualise each process on any selected operative panel.

Drive technology

We have a long-term experience in launching Siemens Sinamics mechanisms in versions G and S, which does not mean that we focus only on these mechanisms. We can also implement the SEW or Lenze mechanisms.

Launching of production stations and lines

We offer you participation in launching a production station or line. It includes preparation of an offline programme in accordance with the standard of machine programme at your facility or creating such standard and launching online at the manufacturer’s or end customer’s facility.

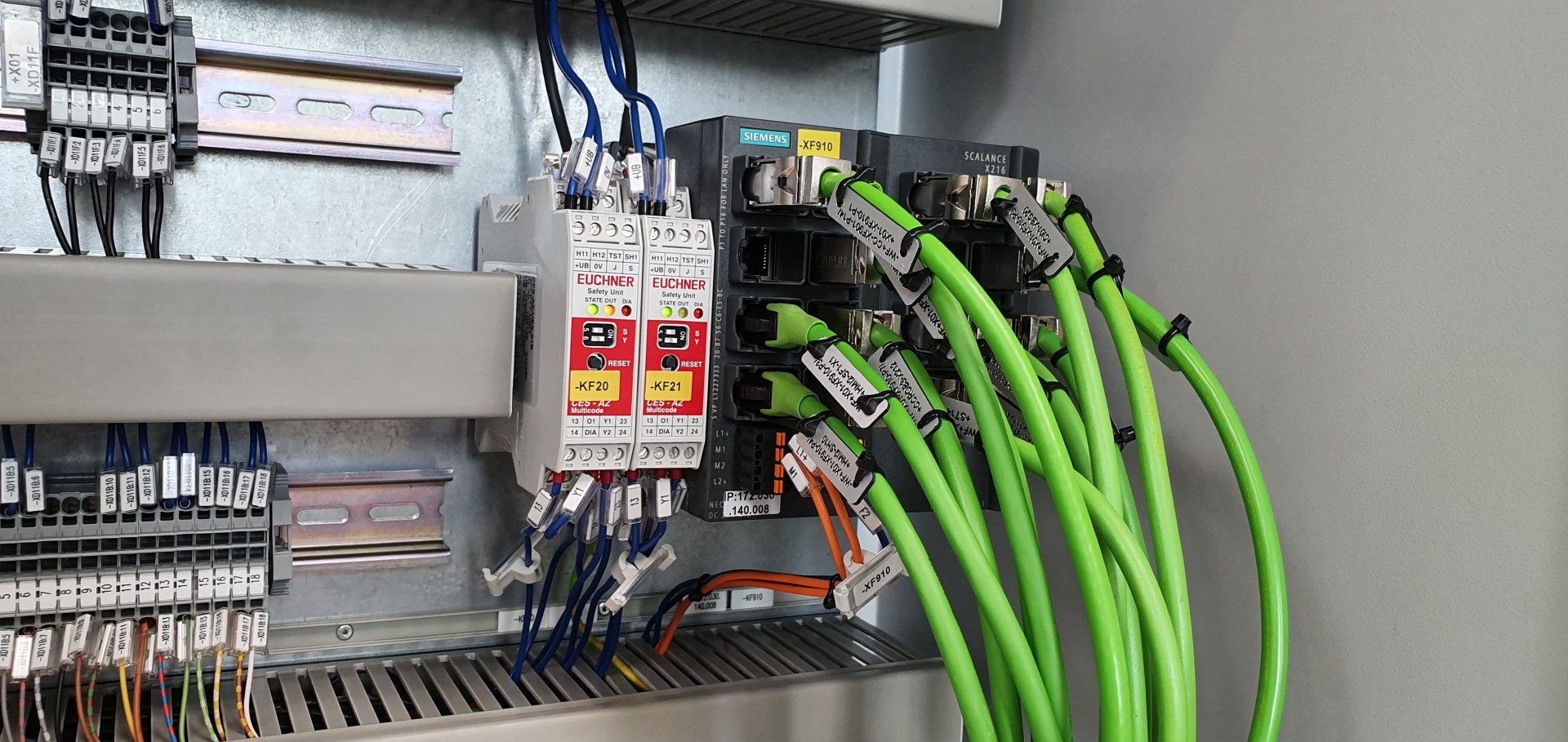

Safety of machinery

We select, launch and test safety systems. We will programme dedicated controllers (Sick, Pilz) or integrated with the PLC controller – Failsafe (e.g. Siemens, version F). We will launch a 3D safety scanner (Pilz SafetyEye), 2D scanners (e.g. S3000), and we will configure peripheral equipment for working with safety devices. All these in accordance with the applicable standards and hardware possibilities.

Design and selection of control systems

We choose as well as help in selection of a controller, HMI panel, IO peripheral equipment, communication method, interfaces and concept of machine safety.

Robotics

The robot works 24 hours a day, and it does not need any breaks. It does not lodge an application for leave or sick leave. That is why it is worth considering optimisation of processes by using robots. This investment will quickly pay for itself and the company’s reputation is increased.

We offer assistance from analysis of profitability of robot implementation (including, but not limited to, such manufacturers as Kuka, Fanuc, ABB, Yaskawa or Kawasaki) to the existing machines up to their launching and programming. We offer support and maintenance services.

Optimisation of manufacturing processes

Cycle time is too long? Contact us. We will certainly find a solution.

Consultancy and service

We will tell you whether a particular device or technical solution will work in a given system.

After each implemented system, we offer support, training and on/offline help.